������

��

����������

Industrial Separation & Process Solutions

IGF ATMOSPHERIC RAV and EAV SERIES

Atmospheric Induced Gas Flotation Units

w w w. h u d s o n i n d . c o m

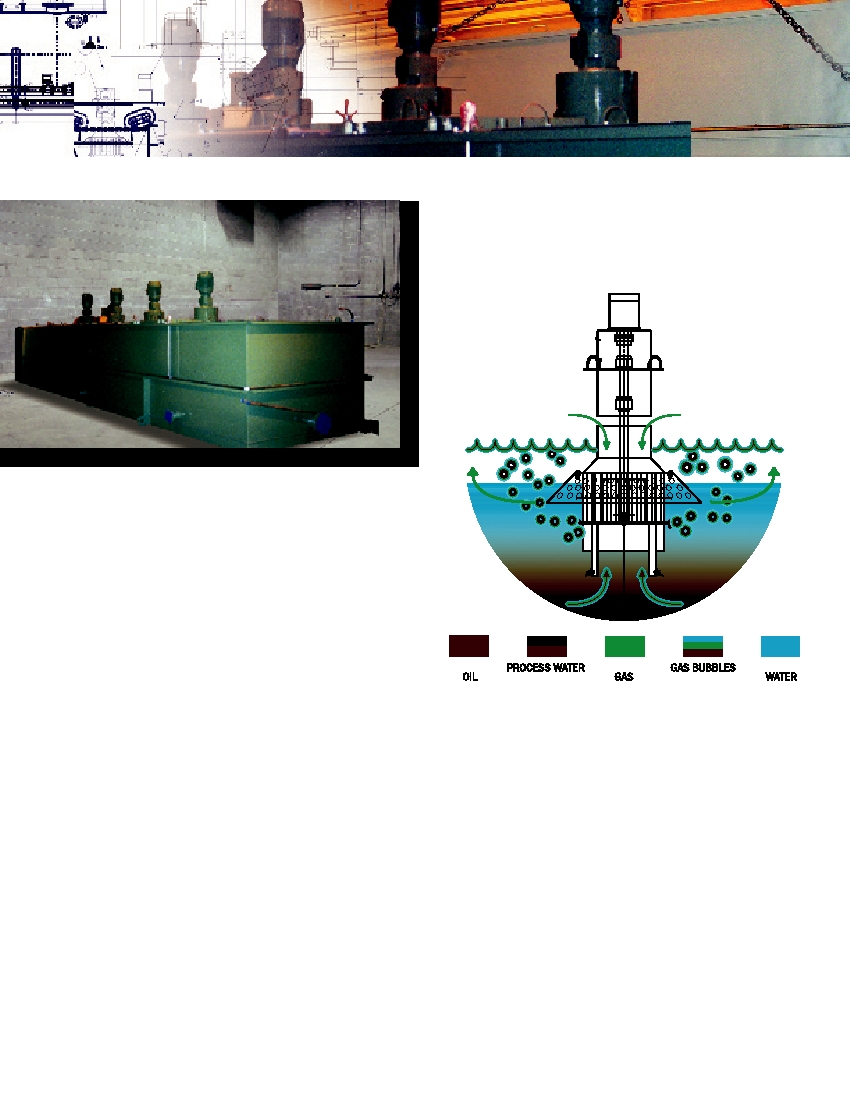

INDUCED GAS FLOTATION - RAV UNITS

driven rotor assembly, draft tube/stator/disperser

assembly, and independent skimmer, allowing for

stage separation, with each active cell capable of

approximately 75% removal of oil with a composite

efficiency range of 95-99%.

Atmospheric RPV Unit

Hudson Industries designs and manufactures

pressurized Induced Gas Flotation units in standard

models from 10 to 8000 GPM. The RAV Series of

equipment are mechanically-induced IGF units.

The EAV series of equipment are hydraulically-

educted IGF units. Both types of equipment are

available in ASME code pressure vessels for a wide

range of operating pressures, temperatures and

process applications.

INDUSTRIES SERVED

As the rotor spins in the process fluid, it creates a

vortex inside the draft tube, drawing the process

·

Offshore/Onshore Produced Water Treatment

gas down from the top of the vessel into the

·

Process Oily Water Treatment

disperser assembly. The process fluid is then drawn

·

Petrochemical and Refining

up through the standpipe and into the stator. The

·

Power Generation

gas, forced through the stator, shears into the

process fluid creating a continuous gas bubble

·

Food Processing

flow of optimum size for efficient separation. The

·

Pulp & Paper

bubbles pass through the stator skirt assembly,

·

Steel Manufacturing

ensuring even distribution throughout the cell due

·

Environmental

to its unique design.

·

General Heavy Industry

The rising bubbles attach themselves to oil droplets,

RAV UNITS PRINCIPLE OF

lifting them to the surface. As with all flotation

OPERATION

machines, flotation chemicals are used to assist in

the separation process. The bubbles form an oil

The IGF unit is equipped with four independently

floc as they reach the surface, which is skimmed off

operating cells. Each cell is equipped with a motor-

via adjustable skimmers.

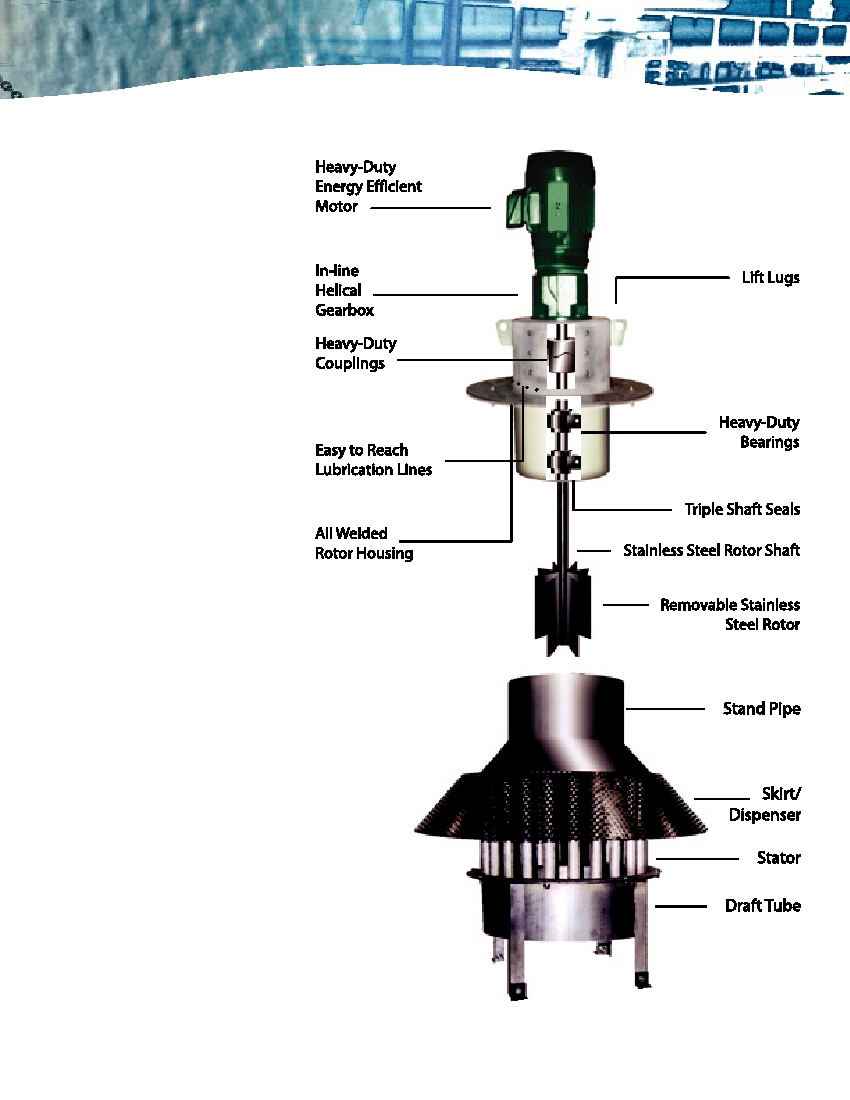

ROTOR DESIGN

Hudson Industries offers a unique

removable rotor assembly. All

Hudson IGF units are equipped

with an inline helical gearbox with

double shaft seals for extended

life, without oil leaks. Motors

are heavy-duty energy efficient.

Heavy-duty bearings can be

supplied by most manufacturers

worldwide for reduced spare

parts cost. Removable rotor

blade assemblies can be easily

replaced or repaired in the

event of tip wear or erosion. All

equipment is available in a wide

variety of materials to suit even

the most severe process.

ELEMENTS OF THE RAV SYSTEM

·

Four cell horizontal vessel or vertical mono-cell design

·

Fully skid-mounted and ready for installation

·

ASME "U" Stamp pressure vessels

·

Extensive range of vessel and

internal materials

·

Variable speed drives on rotors for speed control

·

Suitable for a broad range of operating gases

·

External adjustable float skimmers

·

Low skim rate

·

Built in chemical injection points

·

Heavy-duty phenolic epoxy

vessel linings

·

High efficiency operation

·

Low operation costs

·

Direct drive rotor assemblies

·

No belts or sheaves

·

Removable internals

Model of Rotor and Skirt Assembly

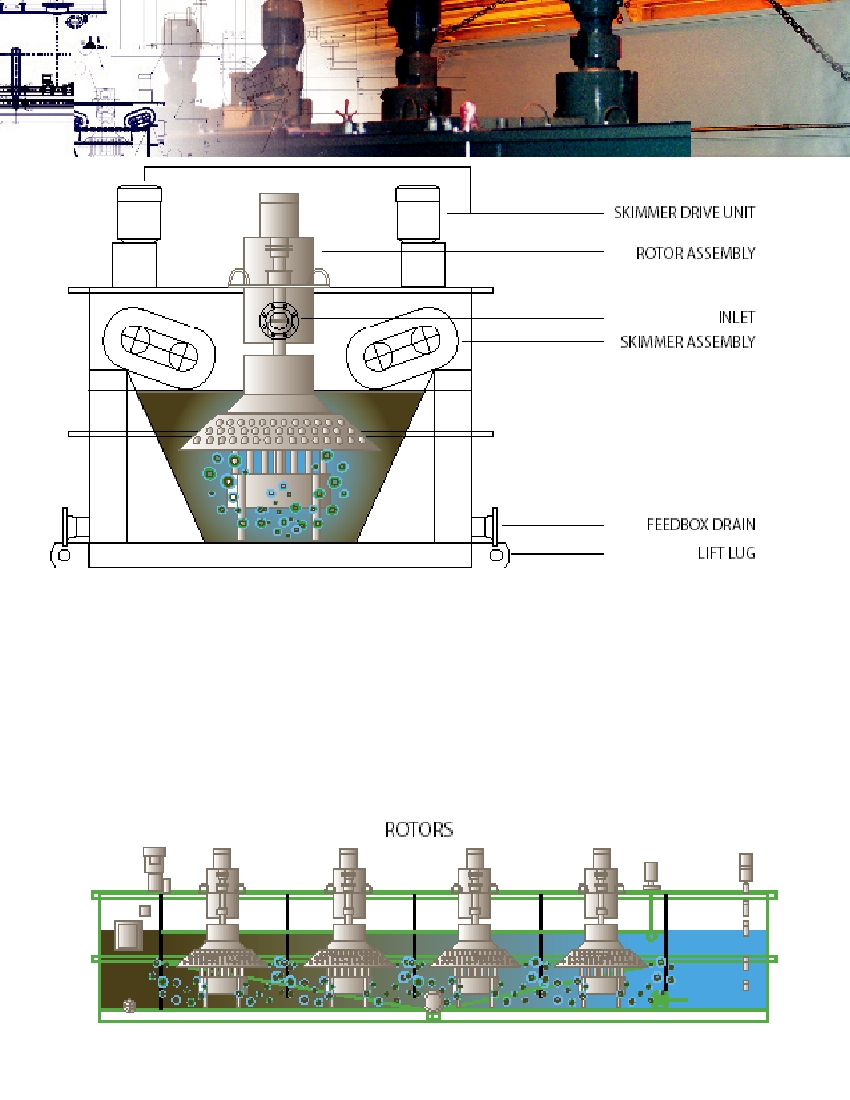

Inlet View

SKIMMER - PRINCIPLE OF OPERATION

Hudson Industries'

unique adjustable float

determined by a level indicator on the adjustment

skimmer allows for a broad range of operating flows,

screw. Skim rates can be set or changed should the

from a fraction of rated flow to 100% of rated flow.

viscosity and/or loading of the separated product

The adjustable skimmer is mechanically operated

change, without having to stop the process. Typical

from outside the vessel, with the position being

skim rates are 3%-8% of feed flow.

Model of Atmospheric RAV Unit

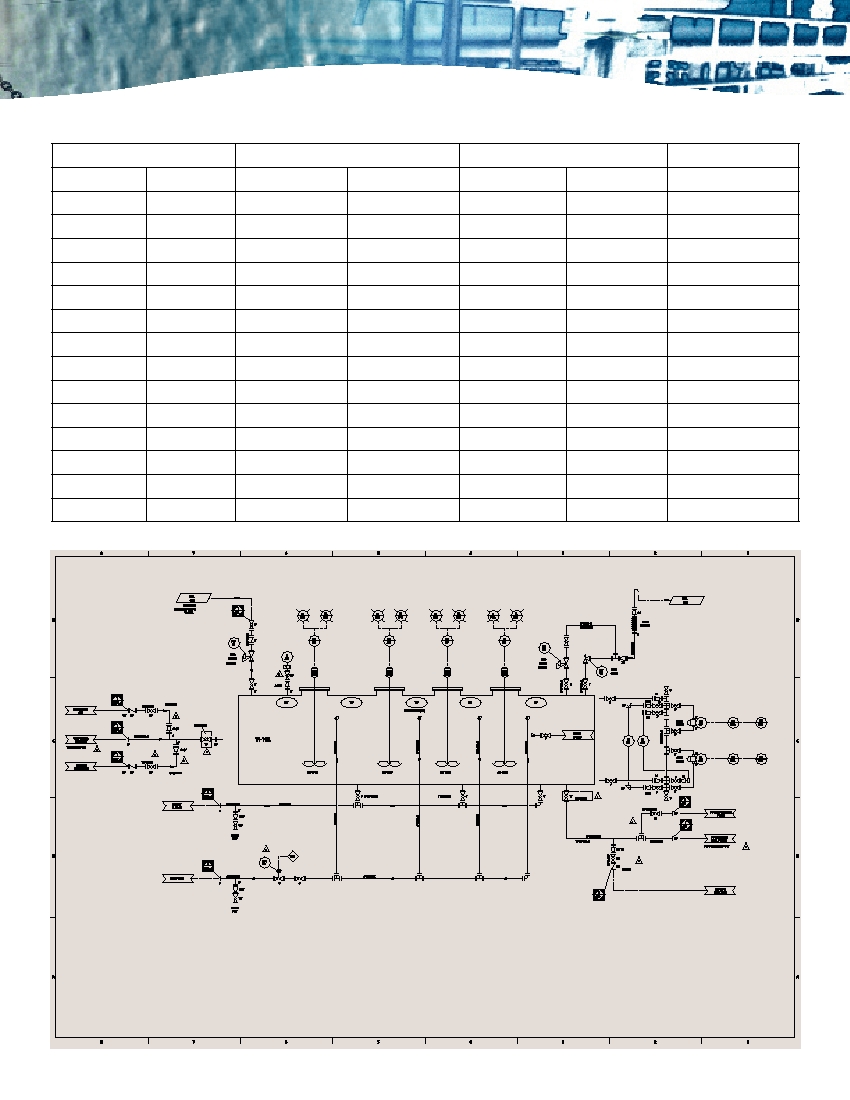

RAV SIZES

CAPACITY

VESSEL

ROTOR

OP. WEIGHT (LBS)

MODEL

GPM

DIAMETER

TOTAL LENGTH

DIAMETER

HP

(LOW PRESSURE)

RAV-25

25

24"

128"

5"

1

3,500

RAV-50

50

30"

161"

6"

1.5

6,000

RAV-100

100

38"

203"

7"

2

10,300

RAV-200

200

48"

256"

10"

5

18,100

RAV-500

500

65"

347"

13"

7.5

38,900

RAV-800

800

76"

347"

15"

10

66,000

RAV-1000

1000

82"

406"

16.5"

15

79,900

RAV-2000

2000

103"

551"

21"

20

144,400

RAV-3000

3000

118"

631"

24"

30

225,000

RAV-4000

4000

130"

694"

26"

40

288,000

RAV-5000

5000

141"

748"

27"

50

343,000

RAV-6000

6000

141"

805"

30"

60

400,000

RAV-7000

7000

155"

853"

33"

75

459,000

RAV-8000

8000

170"

900"

35"

100

500,000

Typical Process and Instrumentation Diagram for

Pressurized RAV Unit

INDUCED GAS FLOTATION - EAV UNITS

PRINCIPLE OF OPERATION

The IGF is divided into four operating

cells, one feed cell, and one discharge

cell. Process water enters the IGF

through the feed cell then flows

into the first process cell. All process

cells are equipped with individual

gas eductors which are connected

to a single or duplex recycle pump.

The recycle pump draws processed

water from the discharge chamber

and pumps it back to the process

chambers through the gas eductors.

As the water passes through the gas

eductors, process gas is induced

into the water and pumped down a

nozzle to a distributor.

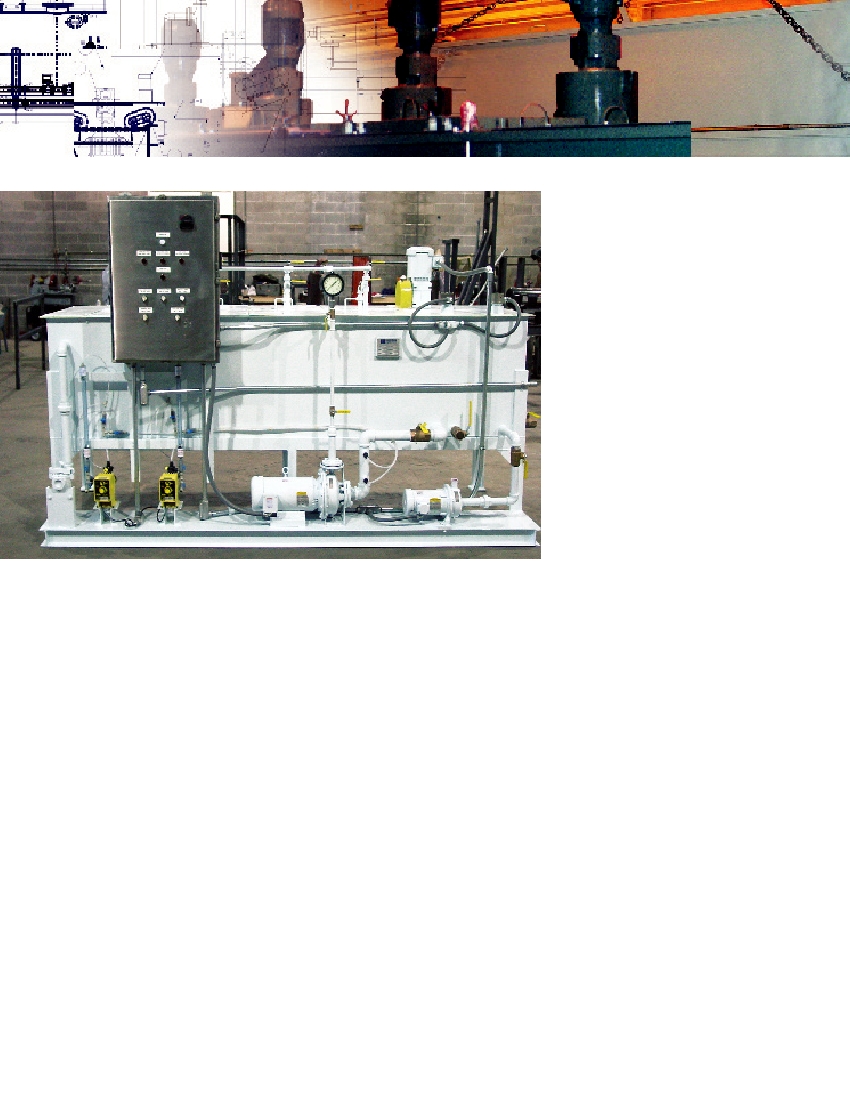

Atmospheric Naturally Aspirated EAV

As the water/gas exits the distributor, the immediate

release of gas creates small bubbles, which rise to the

surface. This continuous stream of bubbles, along

with the use of separation chemicals, carries the

THE EAV INDUCED

oil droplets to the surface where they form an oily

GAS FLOTATION SYSTEM

froth (float). As the float accumulates, it is skimmed

off each cell through an adjustable skimmer. Each

Hudson Industries designs and manufactures

eductor is equipped with control valves on both the

hydraulically-educted induced gas flotation units

gas and water to enable the unit to be adjusted to

from 10 to 8000 GPM. While less efficient than the

optimum bubble size and performance.

RAV series of equipment, the EAV units are ideally

suited for gross separation of hydrocarbon products

Hudson Industries IGF Engineers

have

and solids.

extensive experience in equipment and process

design for oily wastewater treatment.

This

All EAV units are self-contained with no external air

experience allows us to provide a high quality

supply required, or can be supplied with gas control

product built to your needs. Hudson Industries

systems for use with gases other than air.

can provide complete engineering and equipment

packages to handle any oily water problem.

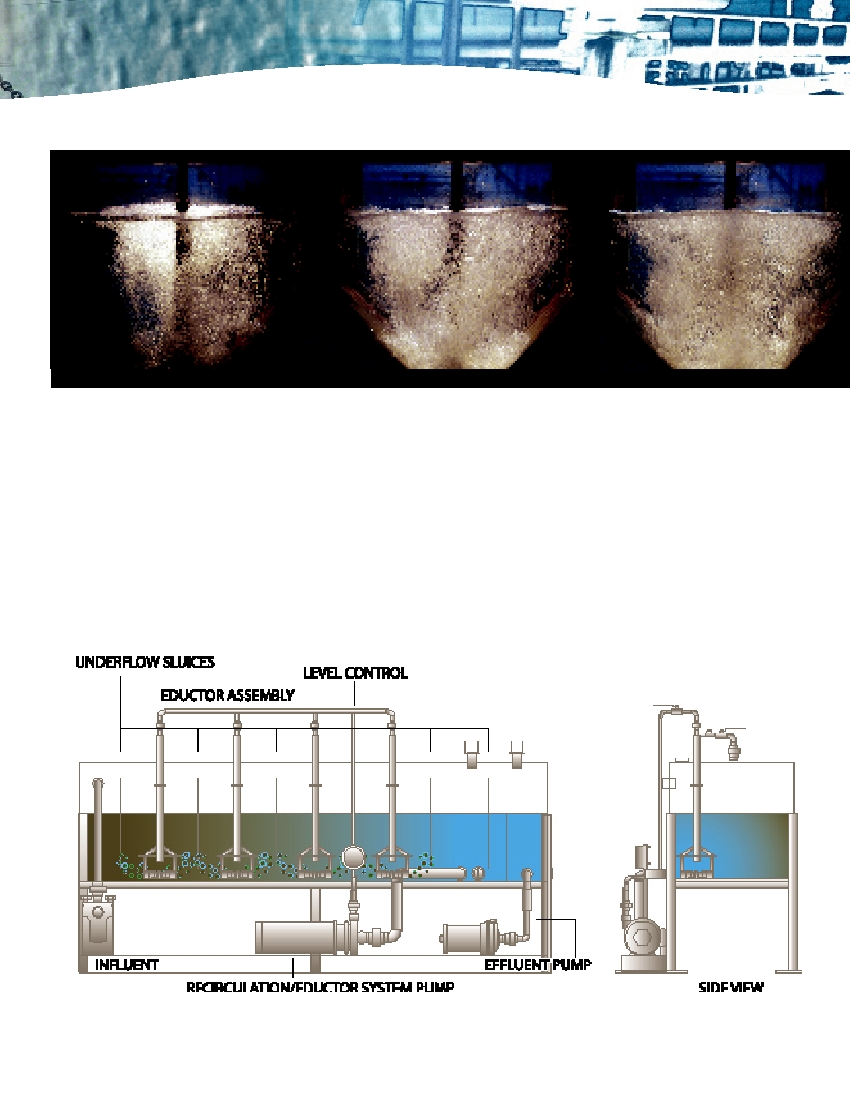

Studies of the Optimum Bubbling Capability of the EAV Model

ELEMENTS OF THE EAV SYSTEM

· Four cell horizontal vessel or vertical

·

External adjustable oil skimmers

mono-cell design

·

Low skim rate

· Fully skid-mounted and ready for installation

·

Built in chemical injection points

· Broad range of vessel materials and

·

Heavy-duty phenolic epoxy vessel linings

internal materials

·

Low operation costs

· Suitable for a broad range of operating gases

·

Few moving parts

Model of Atmospheric Aspirated EAV

������

��

����������

Industrial Separation & Process Solutions

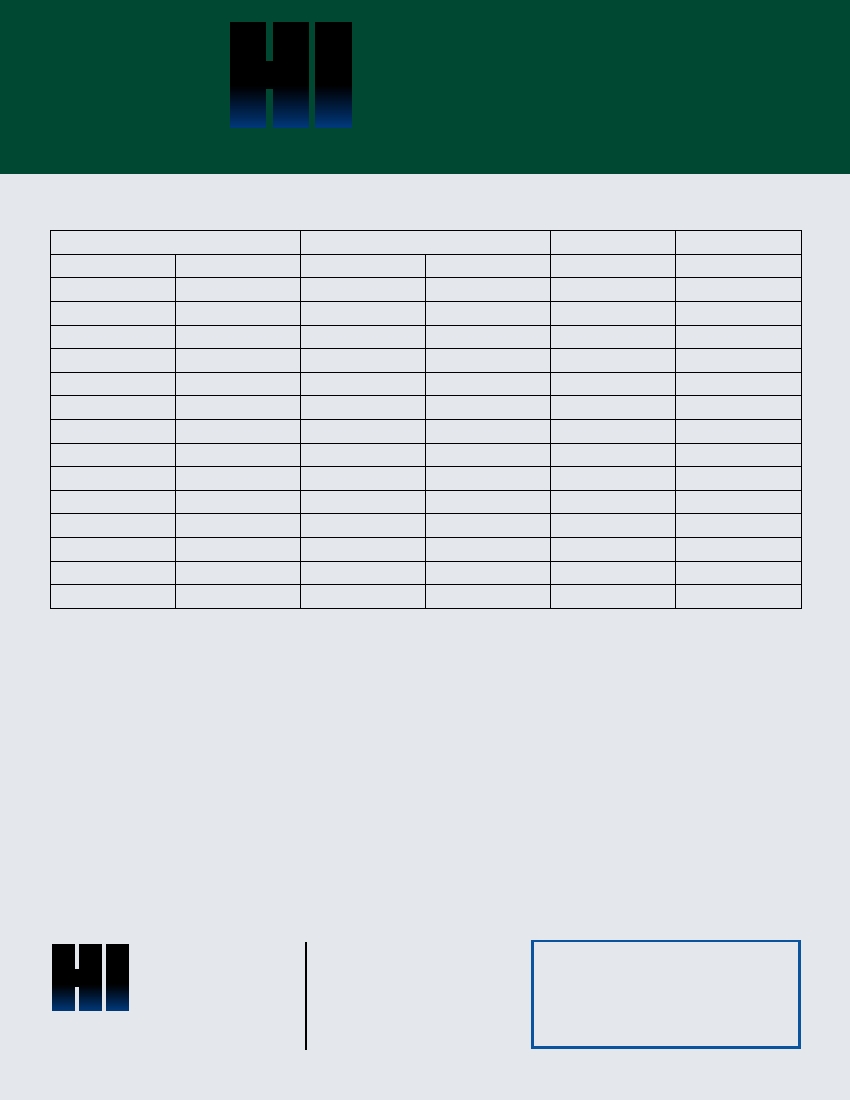

EAV SIZES

CAPACITY

VESSEL

RECYCLE PUMP OP. WEIGHT (LBS)

MODEL

GPM

DIAMETER

TOTAL LENGTH

HP

(LOW PRESSURE)

EAV-25

25

24"

128"

7.5

6,500

EAV-50

50

30"

161"

10

8,500

EAV-100

100

38"

203"

15

12,500

EAV-200

200

48"

256"

20

19,500

EAV-500

500

65"

347"

30

38,000

EAV-800

800

76"

347"

50

64,000

EAV-1000

1000

82"

406"

60

100,000

EAV-2000

2000

103"

551"

75

160,000

EAV-3000

3000

118"

631"

100

180,000

EAV-4000

4000

130"

694"

150

200,000

EAV-5000

5000

141"

748"

200

225,000

EAV-6000

6000

141"

805"

200

245,000

EAV-7000

7000

155"

853"

250

270,000

EAV-8000

8000

170"

900"

300

290,000

OPTIONS FOR THE RAV AND EAV UNITS

·

Vertical mono-cell designs

· Transfer pump packages

·

Complete skid-mounted packages

· Chemical feed packages

·

Explosion-proof systems

· Upstream and downstream treatment

·

Exotic vessel and internal alloy materials of

equipment

construction

· Maintenance and operation contracts

· Insulation

· Lease Plans

· PLC control systems

· Onsite testing services

If you don't see what you need, our experienced engineers will design a system

to meet your exact specifications.

������

39 E. market st. suite #401

��

akron, oh 44308 usa

office: 330-794-2020

����������

Industrial Separation & Process Solutions

fax: 330-794-2021

w w w. h u d s o n i n d . c o m

e-mail: info@hudsonind.com

Your Local Sales Contact

Bulletin IG14-705 0M ©2005 Hudson Industries